|

Knowledge is Powerful

|

|

To meet these business-critical demands, maintenance professionals need to maximise machine reliability whilst minimising maintenance costs - a very difficult balancing act indeed.

Knowledge is Powerful

Multi Maintenance Solution understands that “knowledge” is key solution to eliminate your problems! We developed our courses based on the extensive knowledge we gathered from different industries over the decades through close collaboration with our customers to meet their needs.

Multi Maintenance Solution offers a comprehensive range of courses that covers every aspect of machine reliability - from the shop floor to the executive office.

The course portfolio has been designed to allow participants to gain the knowledge and expertise in a structured development path. These courses are designed for managers and engineers.

|

|

|

|

|

Maximise your knowledge

No matter what industry you're in or what type of machinery you use, Multi Maintenance Solution courses are designed to help you maintain and manage your assets more efficiently. By choosing the right training courses and applying your knowledge correctly, you will be able to eliminate machinery problems and achieve maximum reliability and productivity. Therefore, upgrading your current maintenance strategy to the next level towards Proactive Maintenance. |

Maximise your subsidized contribution !

All our courses all fully claimable under HRDF scheme. So why wait? Start grooming your staffs today with your subsidized contribution. Contact us for more information. |

| |

|

|

|

Benefits of training

• Improving participants knowledge and skills by interactive classroom training, case study and practical hands-on.

• In-depth training delivered to you by experts in the field.

• Interact with others facing the same problem you are.

• Opportunity to ask questions face-to-face about the problems you are currently dealing with and examine real-world applications.

• Take you to the next level of your career

|

|

|

|

Training Course Classification

Multi Maintenance Solution offers a blend of courses and locations to meet your specific training requirements. On-site training is available at your plant or training facility bringing the “knowledge and experience” closer to you. We categories all our courses and trainings into 3 level of syllabus.

|

|

|

|

Entry Level

These courses are designed to introduce participants to the subject that covers the fundamental principal, product knowledge, basic designation / numbering system and basic theories. |

|

| |

|

Intermediate Level

The Entry Level courses are considered the pre-requisites for these Intermediate courses. These courses cover more in-depth in designing and selection, specific application, methodology, product features and functions as well as calculation and practical hands-on. |

|

| |

|

Advance Level

Is recommends for participants to have undergone Intermediate Level courses and with site experience before attending Advanced Level courses. These Advanced courses emphasize in specialize topics such as Predictive Maintenance Programs, Vibration Analysis, Infrared Thermography, RCFA, customize syllabus for specific industry and application. These courses are delivered by our field expertise trainers. |

|

Training courses overview

Professional Training Available to your door-step

Training courses listed here are available and can be customise to suit your needs and requirements. These trainings can be organised at your plant or training facility with prior reservation arrangement.

|

|

|

Bearing Maintenance & Application - General Level

This course is suitable for all levels of personal with no pre-requisition requirements. The course provides fundamental knowledge of rolling bearing types, designs and geometry, components and its functions, understanding of numbering system and suffixes, and a brief approach in replacement and maintenance of rolling bearings in most common type of the rotating equipment.

|

|

Bearing Installation & Inspection

This course is recommended for technical personal who need to maintain a bearing. The course covers the correct methodology and procedures for bearing mounting and dismounting, observe what happens as a result of careless handling, neglected maintenance and poor lubrication. Participants will have practical hands-on using specialized tools to correctly mount and dismount ball / roller bearings.

|

|

Lubrication – Basic

This course is primarily for greaser / oiler, technical personal entering the lubrication field and maintenance staffs. Basic Lubrication is an introduction course to lubricants, lubrication principles and physics properties of lubricants. The course also includes selection of lubrication, replenishment period and quantity calculation and lubricant usable temperature limits.

|

|

Reliability & Proactive Maintenance Program

This course is ideal for people who need to know what reliability and proactive maintenance is all about. To ensure a more successful and effective program, understand the goals and benefits is essential. This course includes an overview on maintenance strategies, practical steps that can be implemented to improve reliability, condition monitoring technologies, and how they can provide early warnings about possible machine failure.

|

|

Bearing Maintenance & Application – Advance Level

As a subsequent course from the general “Entry Level”, the Advance Level course focuses more details in bearing manufacturing technology and processes, bearing expectancy life calculation, selection of shaft / housing fitting tolerance, internal clearance setting, bearing arrangement and lubricant replenish period.

|

|

Bearing Root Cause Failure Analysis Course (RCFA)

The course helps participants to identify and interpret premature bearing failures. The course covers root causes of bearing failure from specification and purchase to shipping and storage, installation, lubrication, contamination and vibration among other things. It will contain in depth case studies on bearing wear path patterns recognition for common defects such as misalignment, lubrication, vibrations and electrical fluting.

|

|

Gearbox Maintenance Course

This course will provide the participant with the knowledge needed to properly maintain, service, inspect and repair a variety of Industrial gearboxes. The course will allow the participant to learn gearing terminology, to properly “set” the gears and “preload” the bearings and proper lubricant selection for maximum life expectancy. Correct methodology for bearings, seals and gears replacement is included as well in the course.

|

|

Precision Alignment Course

This course focuses on steps and procedures required to obtain a precision alignment. It provides an overview of the benefits of alignment, soft foot correction, laser alignment methods, tolerance specifications, documentation, reporting and how to move the machine. Participants will be capable to perform measurements and alignments with laser based systems independently.

|

|

Lubrication - Advance

As a preceding course from the Lubrication Basic, this Advance course stretches more details on management such as storage and handling, sampling and analysis, contamination control, task planning and scheduling. An effective lubrication management program will reduce the overall costs of lubricating and maintenance significantly. It will also create safer working conditions and reduce the overall environmental impact.

|

|

Vibration Analysis Course

Vibration analysis training allow students to select the correct sensors and data acquisition technique, they learn to interprets vibration signatures and diagnose machinery malfunctions from this data. Vibration analysis training prepares students to isolate a problem machine part and make recommendations for scheduled repairs or continued operation.

|

|

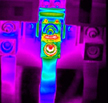

Infrared Thermography Course

The Infrared Thermography Course is geared to the new infrared camera user and focuses on its use for a variety of condition monitoring/predictive maintenance applications. Students will learn to collect quality data with account of measurement effects such as distance and emissivity, interpret thermal images using heat transfer concepts, and learn to distinguish between hot spots and reflections.

|

|

Online Condition Monitoring System

An overview course that give you a general ideas and guidelines on critical application that requires to be monitored online as a proactive step for cost reduction solution. In this course, students will understands the objectives and benefits of online condition monitoring system, system selection, monitoring parameters and technique to be use to promote an effective and successful program.

|

|

|

|

|

|