Conversion of information into action!

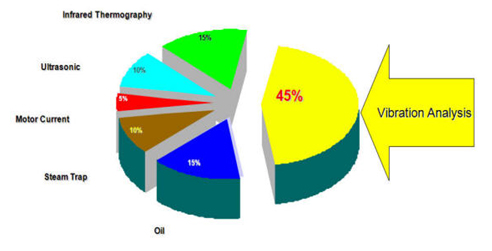

Vibration analysis is a proven technology in determining the reoccurring equipment failure and provides us with early warnings of many potentially serious root sources in rotating machinery that leads to catastrophic failures. Unpredictable or unscheduled equipment failures can cost up to 10 times more to repair than equipment repaired when predicted by condition monitoring. Studies show that implementation of an effective Predictive Maintenance (PdM) program can results in an average reduction of more than 25% on maintenance cost.