| The most common method of a straight line, thickness gauge and your eyes is compared to the "Laser Method." With the eyeball method, as the illustration shows, you measure the alignment of the shaft. Using Laser Shaft Alignment method you have much more accuracy and precision that greatly improves the results from proper alignment. |

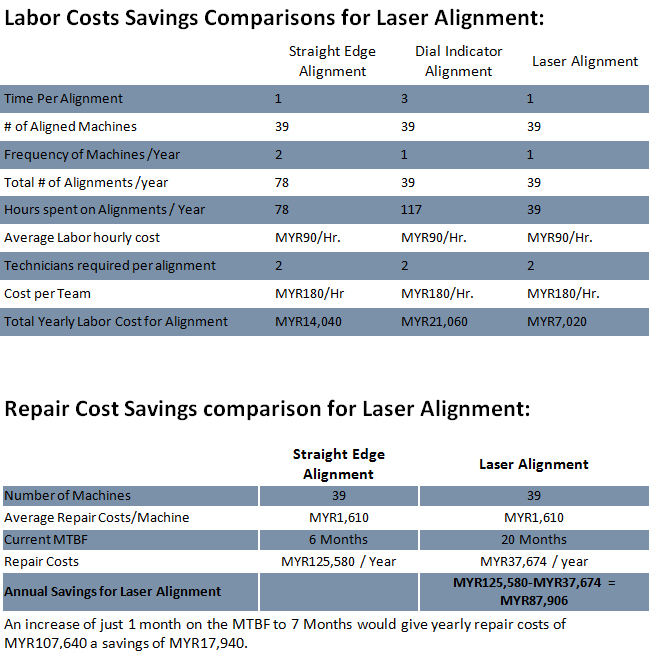

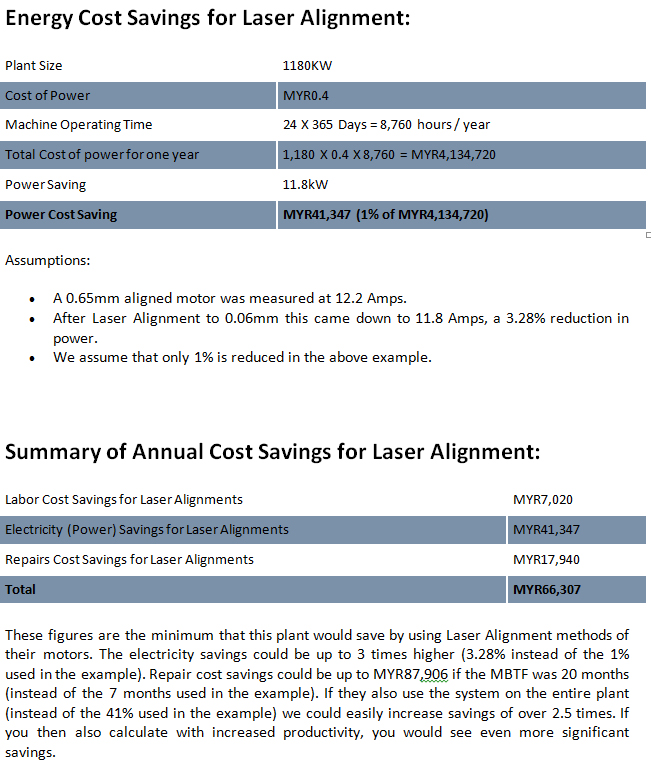

The bottom line is Laser Alignment equipment and services will pay for itself in only a few months.